Laminated Duplex Paper: A Reliable Packaging Solutions

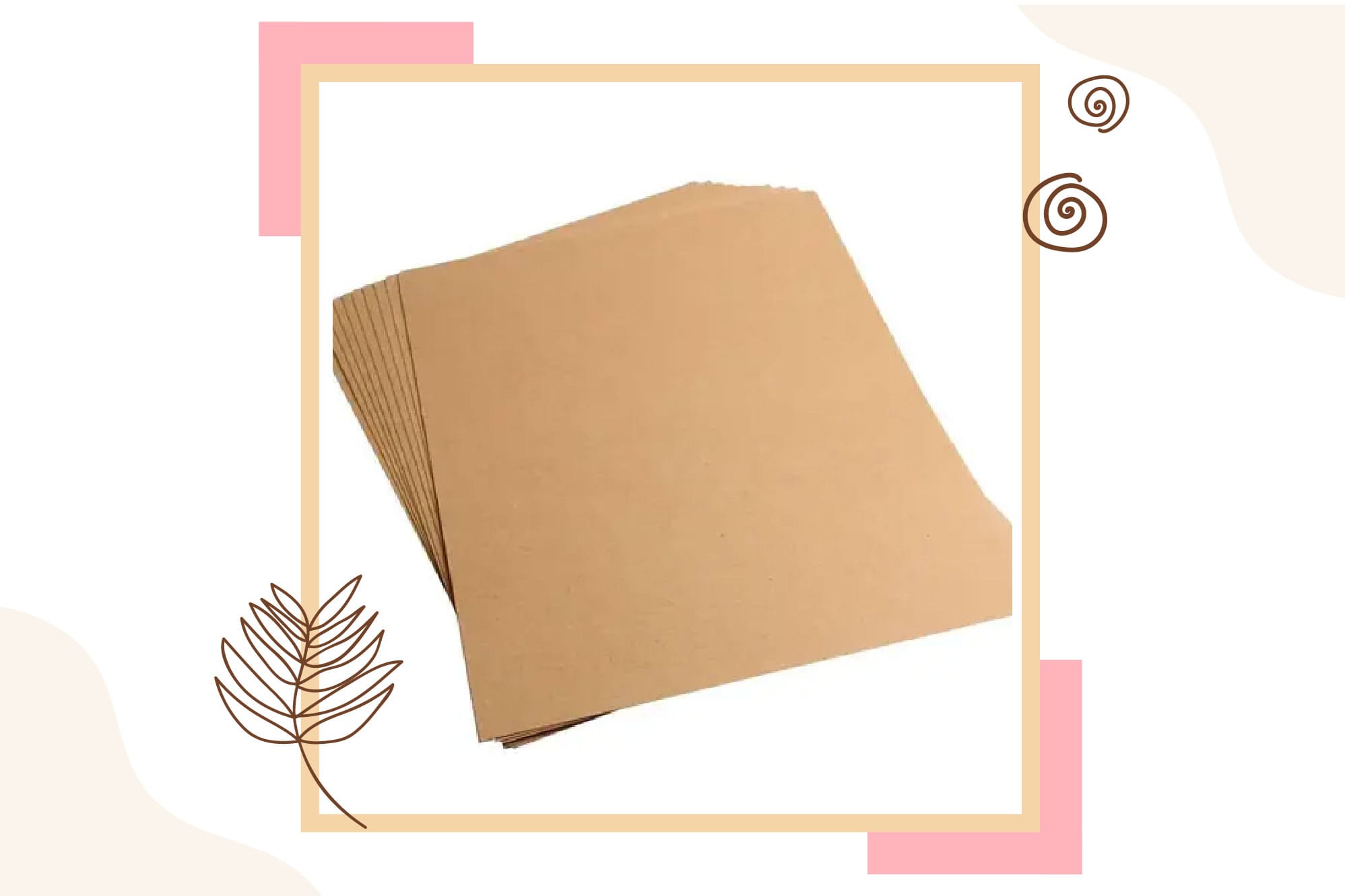

What is Laminated Duplex Paper?

Laminated Duplex Paper is a high-quality paperboard used widely in retail, food, and consumer packaging. It is made by bonding two layers of paper pulp together, with the top layer often coated for a smooth and glossy finish. When laminated, it gains extra strength, durability, and resistance to moisture. This paper is commonly used for making shopping carry bags, cartons, and premium packaging that requires both strength and attractive presentation. It offers a balance of protection and visual appeal, making it ideal for businesses aiming to showcase products professionally.

Material Used in Laminated Duplex Paper

The composition of laminated duplex paper ensures both sturdiness and print-friendliness:

- Duplex Board – Made from bleached and unbleached recycled paper pulp.

- Lamination Film – Water-based or biodegradable film for moisture protection.

- Coatings – Clay-coated surface for smooth printing and finishing.

- Eco-friendly Printing Inks – For branding, logos, and customized designs.

How is Laminated Duplex Paper Made?

The production of laminated duplex paper bags involves these steps:

1. Pulping – Waste paper or wood pulp is processed into duplex board.

2. Layering – Two sheets of paper are combined to form a strong base.

3. Coating – The outer layer is treated with clay or chemicals for a smooth surface.

4. Lamination – A thin protective film is applied for water and grease resistance.

5. Cutting and Conversion – Sheets are cut and shaped into bags or cartons.

6. Printing – High-quality printing techniques are used for branding.

Product & Usage of Laminated Duplex Paper Bags

Laminated duplex paper is versatile and commonly used for:

- Retail and Shopping – Premium shopping bags for clothing and accessories.

- Food and Beverages – Packaging for bakery items, confectionery, and takeaways.

- Electronics and Consumer Goods – Protective packaging for small gadgets.

- E-commerce and Branding – Custom printed bags and boxes for product delivery.

Its strong structure and glossy finish make it a preferred choice for businesses wanting durable yet visually appealing carry bags.

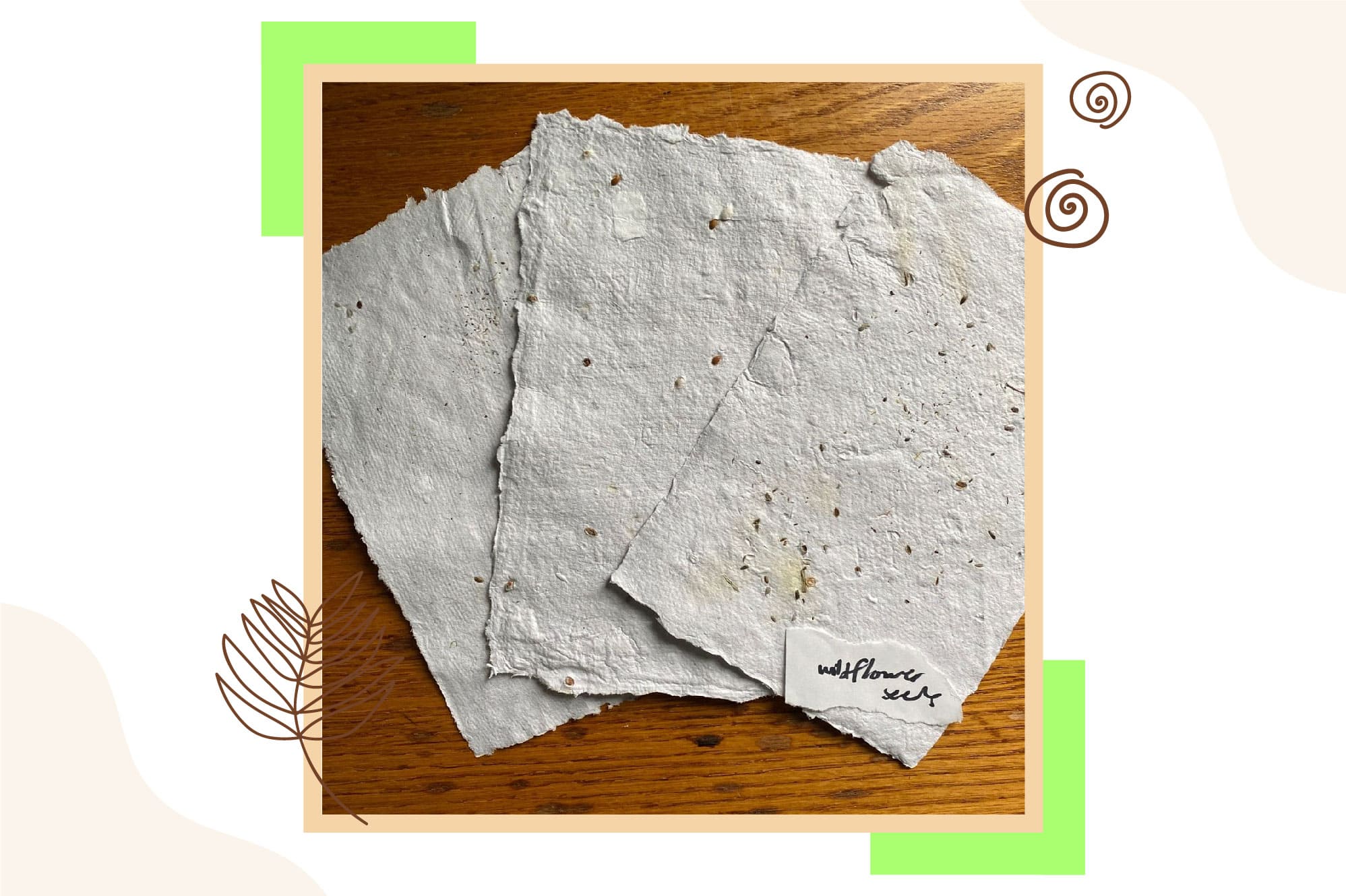

Recycling After Usage

Laminated duplex paper bags can be recycled with proper processing:

- Non-laminated Portions – Recycled into paper pulp and reused.

- Laminated Layers – Separated through specialized recycling techniques.

- Compostable Films – If biodegradable lamination is used, they can decompose naturally.

- Industrial Processing – Converted into secondary packaging materials.

Reproduction After Recycling

After recycling, laminated duplex paper can be repurposed into:

- New Shopping Carry Bags

- Packaging Cartons and Boxes

- Recycled Paper Sheets

- Stationery Products

- Tissue Paper and Wrapping Paper

This cycle helps reduce waste and extends the life of paper fibers.

Why Laminated Duplex Paper is Perfect for Shopping Carry Bags

- Strong and durable – Capable of carrying heavy retail items.

- Attractive finish – Glossy surface enhances product presentation.

- Moisture resistant – Lamination protects against water and grease

- Customizable – Easy to print with branding, designs, and logos.

- Eco-conscious option – Recyclable and available with biodegradable lamination.

.jpg)